- a special in-line dosing system,

- flexible connections of reactor and mixing vessels to the pipe systems or other reactor vessels,

- use of organic solvents or only water,

- mobile vessels,

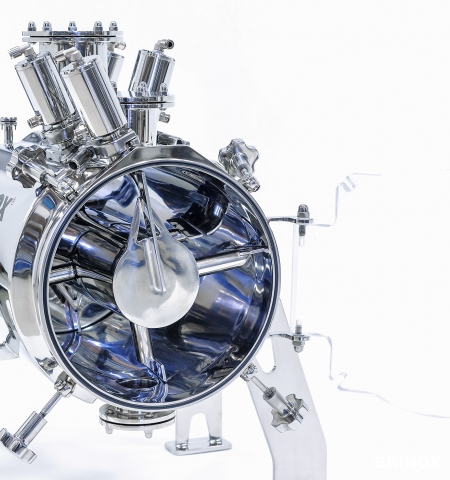

- integrated stirrers depending on the client’s requirements,

- possible connection to a central CIP and DIP skid,

- possible connection to a cooling/heating unit.

Our solutions comply with customer requirements and provide flexible production.