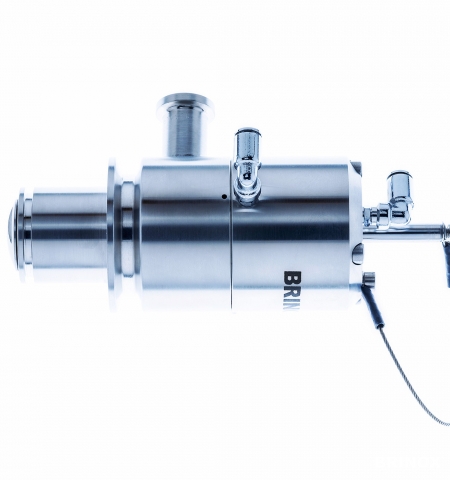

- a special in-line dosing system,

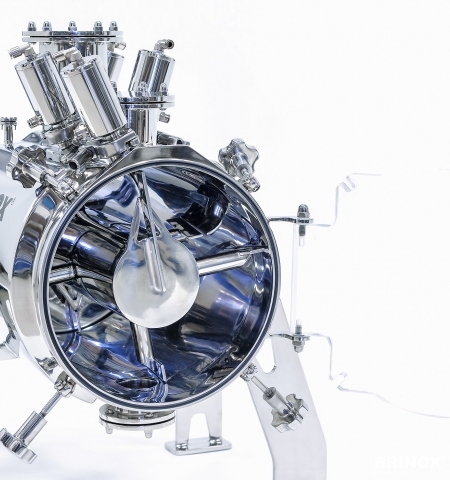

- flexible connections of reactor and mixing vessels to the pipe systems or other reactor vessels,

- use of organic solvents or only water,

- mobile vessels,

- integrated stirrers depending on the client’s requirements,

- possible connection to a central CIP and DIP module,

- possible connection to a cooling/heating unit,

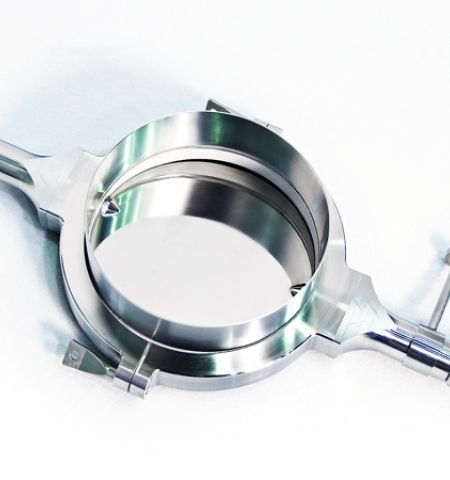

- mechanical finish of all contact and sealing surfaces, sealing without blind spots,

- the use of retractable washing heads for cleaning in place,

- the automated dosing of ingredients and control weighing.

Our solutions comply with customer requirements and provide flexible production.