- are automated using a SCADA system,

- have a long service life,

- have a SMEPAC certificate,

- are built in line with GMP requirements,

- allow for safe operation and management (OEB 3 certificate),

- are easy to maintain and clean, with a lower cleaning medium consumption,

- are equipped with active cooling – after cleaning they are ready for use in 30 minutes (optional),

- have a deaeration valve preventing vacuum (optional),

- the innovative Brinox spray nozzle ensures efficient washing and drying.

Pharma

The docking stations were developed by Brinox experts in close cooperation with the pharmaceutical industry. Dosing and receiving docking stations:

With the Brinox butterfly valves we reach an OEB 1–2, and in case of an additional suction an OEB 3.

The drive can be manual, pneumatic or a combination of both. We design different solutions as requested by the clients.

We produce two types of valves (DN 100, 150, 200, 250, 300):

- with soft flaps for MHS systems for tablets, capsules,

- with stainless flaps for MHS system for granulates, powders.

Brinox cone valves ensure OEB 3 class protection.

The most used conical valve is the DN 400 mm, used especially in cases of poorly flowing powder materials.

The conical valve is installed on the container (IBC).

At the installation site the receiving unit is connected to the process device or receiving container.

The conical valves system produced by Brinox is used for:

- multilevel gravity transfer of powder materials, tablets and capsules,

- single-level gravity system.

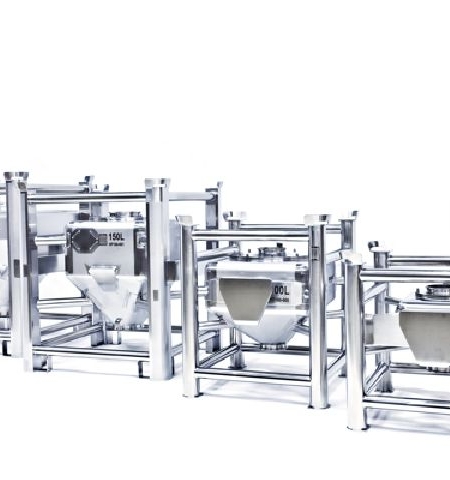

Brinox has developed containers (IBC) of different shapes, sizes (20 – 3500 L) and gripper systems for batch production. Robotic welding and grinding ensure extraordinary dimensional stability of the containers and excellent welds.

We provide also a professional special chemical cleaning procedure that includes the removal of all impurities and passivation of stainless surfaces after welding and grinding.

The inlet and outlet are made in line with the client’s requirements.

Our key advantage is the adaptation to the client’s existing systems and help with the standardisation of MHS systems.